Analysis of a Gen-IV Liquid Salt Cooled High Temperature Reactor

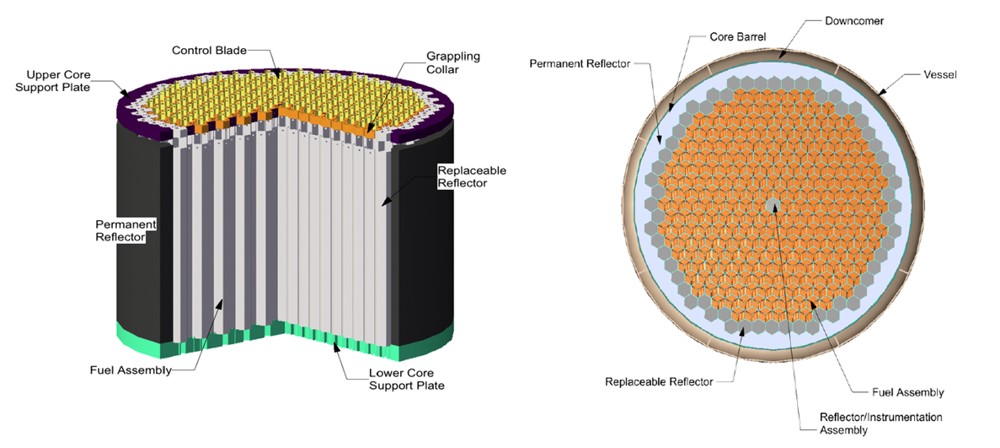

Advanced High Temperature Reactor

- AHTR proposed in 2003 for 3,400 MW power production at high temperature (650 – 750 °C) and low pressure (1 atm) operation with solid fuel form

- High temperature allows for high efficiency electricity production using Brayton Cycle and thermochemical production of hydrogen

- Low operating pressure alleviate need for thick-walled pressure vessels and passive decay heat rejection systems

- Solid fuel form helps minimize coolant radioactivity and prevent fission product corrosion mechanisms

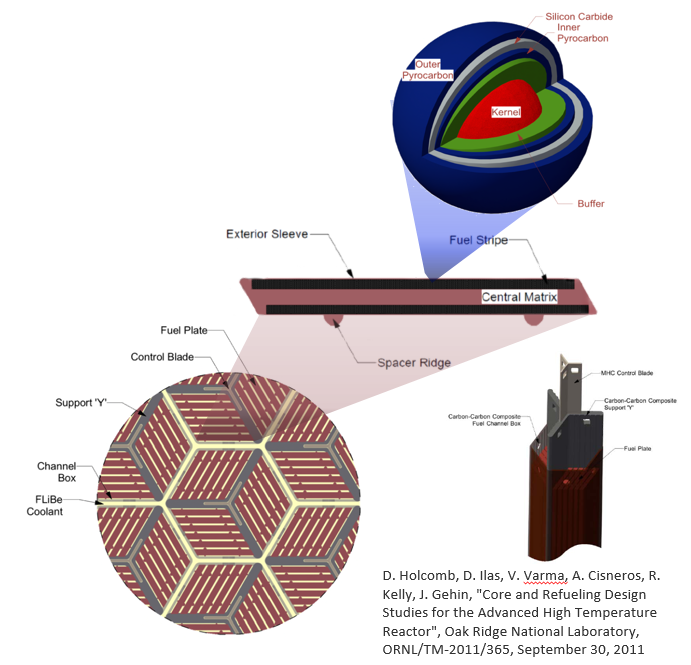

*image: D.E. Holcomb, D. Ilas, V.K. Varma, A.T. Cisneros, R.P. Kelly, J.C. Gehin, “Core and Refueling Design Studies for the Advanced High Temperature Reactor”, Oak Ridge National Laboratory, ORNL/TM-2011/365, September 2011

Fuel Description

- Plank based, graphite moderated fuel form with LiF-BeF2 (“FLiBe”) coolant and embedded TRISO fuel particles

- FLiBe coolant, though expensive, has good heat transfer characteristics, irradiation performance, and low activation

- Plank form provides greater design C / HM ratio flexibility, allows for direct instrumentation, and has enhanced passive cooling capabilities

- Fuel dispersed in two fuel stripe regions for improved heat conduction

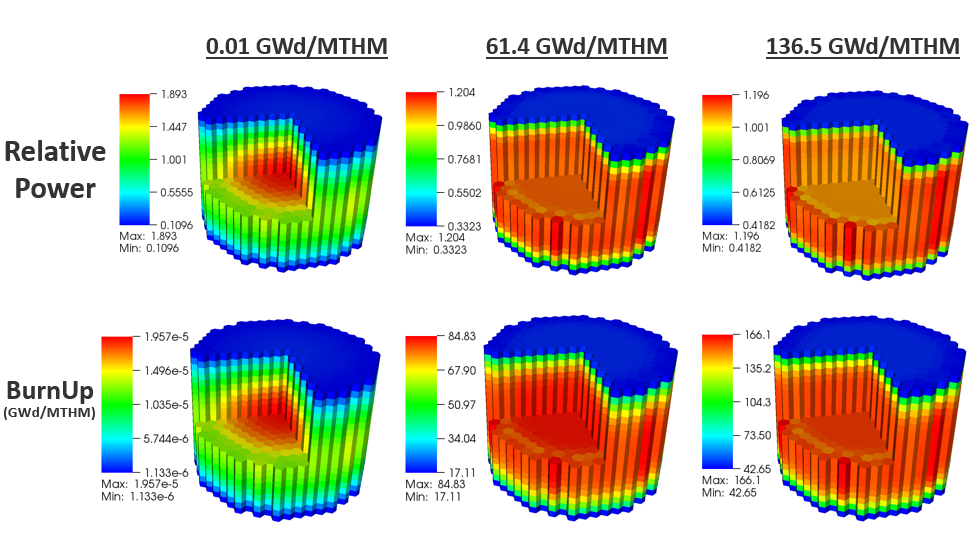

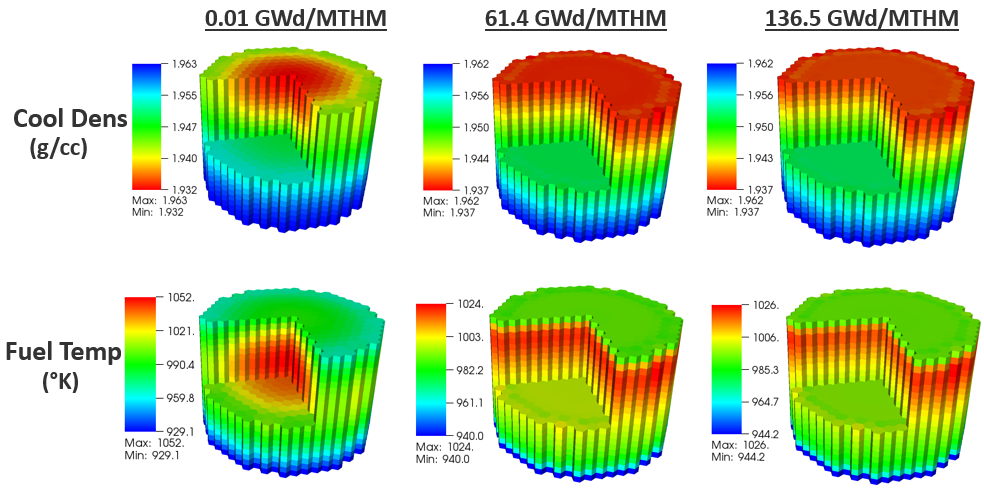

T-H Coupled Simulations

Employing Enhanced Accident Tolerant Claddings in LWRs

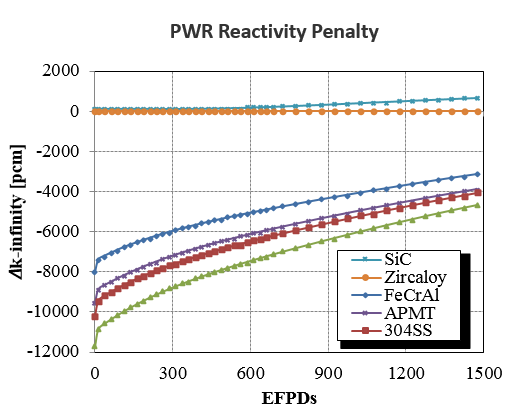

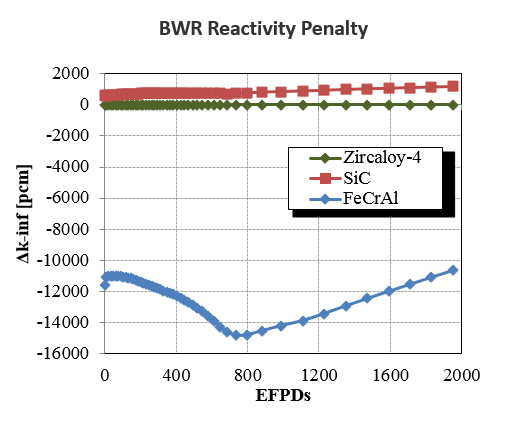

Alternate Cladding Material

- The reactivity of the design has a dependence on the cladding material due to different thermal neutron absorption properties.

- A reduction in overall reactivity can result in the inability to meet cycle length requirements of the reactor

- Depletion of UO2 fuel was calculated in the 2D lattice physics models with the cladding materials

- BWR study focused on FeCrAl and SiC as they performed better neutronically than austenitic cladding options

Full-Core BWR Simulations

- Parametric study performed with FeCrAl bundles in full-core model

- Enrichment and cladding thickness perturbed until matching base case cycle length

- Full-core simulations were consistent with lattice physics results